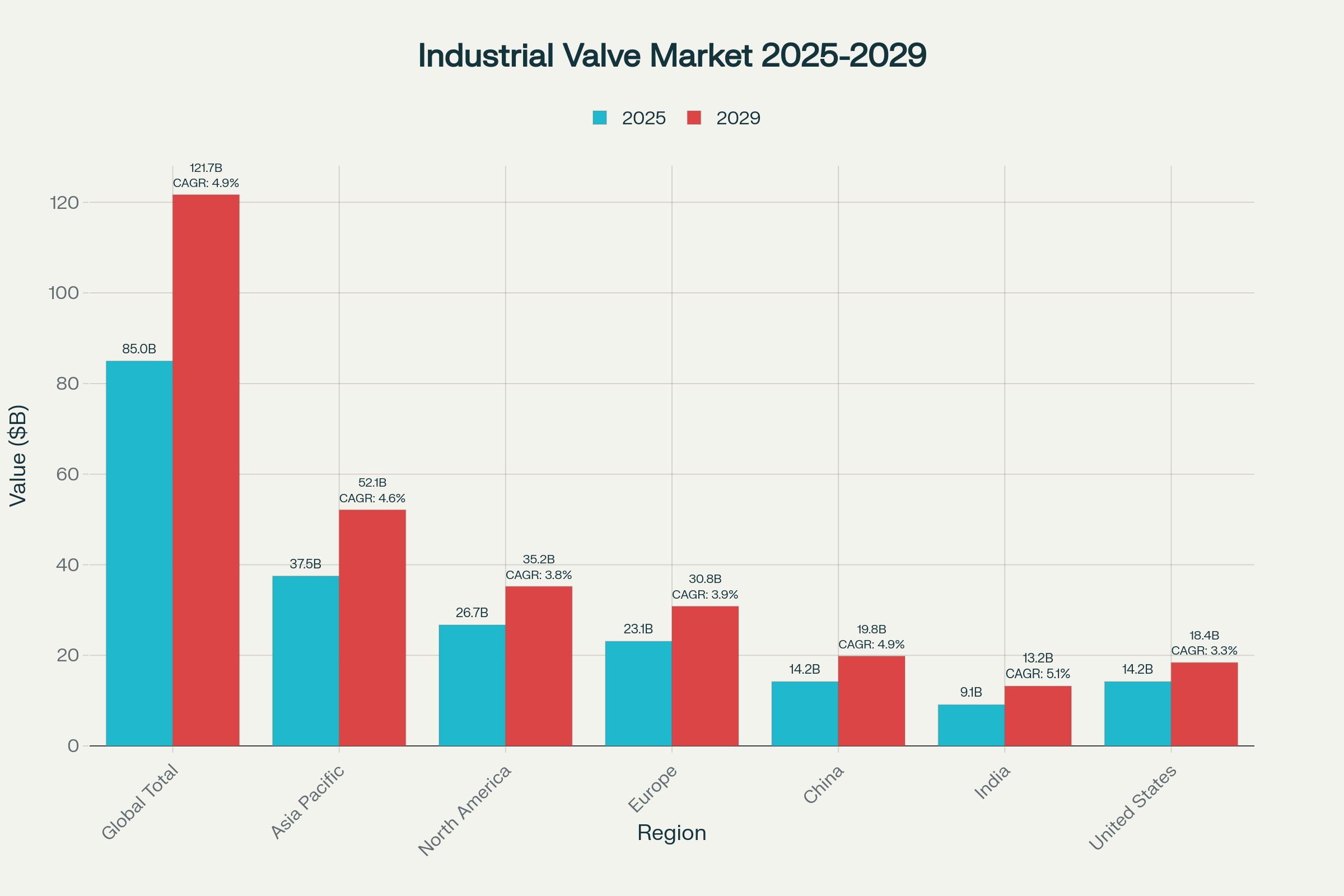

Industrial valves represent one of the most critical components in modern industrial infrastructure, serving as the gatekeepers that control the flow of liquids, gases, and other media through complex piping systems. From the oil rigs of the North Sea to the power plants that illuminate our cities, these precision-engineered devices ensure operational safety, efficiency, and environmental compliance across virtually every industrial sector. The global industrial valve market, valued at approximately $85 billion in 2025, is experiencing unprecedented growth driven by infrastructure modernization, energy sector expansion, and the digital transformation of industrial processes.

This comprehensive report examines the diverse landscape of industrial valves, exploring everything from fundamental valve types and their applications to cutting-edge smart valve technologies and emerging market trends. As industries increasingly prioritize automation, sustainability, and operational efficiency, understanding the role and selection of appropriate valve systems has become more critical than ever for engineers, procurement professionals, and industrial decision-makers.

Understanding Industrial Valve Fundamentals

Industrial valves serve as mechanical devices designed to control, direct, or regulate the flow of fluids by opening, closing, or partially obstructing various passageways within piping systems. These sophisticated components perform multiple functions including flow regulation, pressure control, directional control, and emergency shutdown capabilities. The fundamental operating principle involves manipulating the flow path through mechanical means, whether by rotating a ball, lifting a gate, or positioning a disk.xhval+1

The importance of proper valve selection cannot be overstated, as inappropriate choices can lead to operational inefficiencies, safety hazards, and significant economic losses. Modern industrial facilities rely on thousands of valves working in harmony to maintain optimal process conditions, regulate temperatures and pressures, and ensure safe operations. The complexity of these systems requires careful consideration of multiple factors including fluid characteristics, operating conditions, environmental requirements, and regulatory compliance.

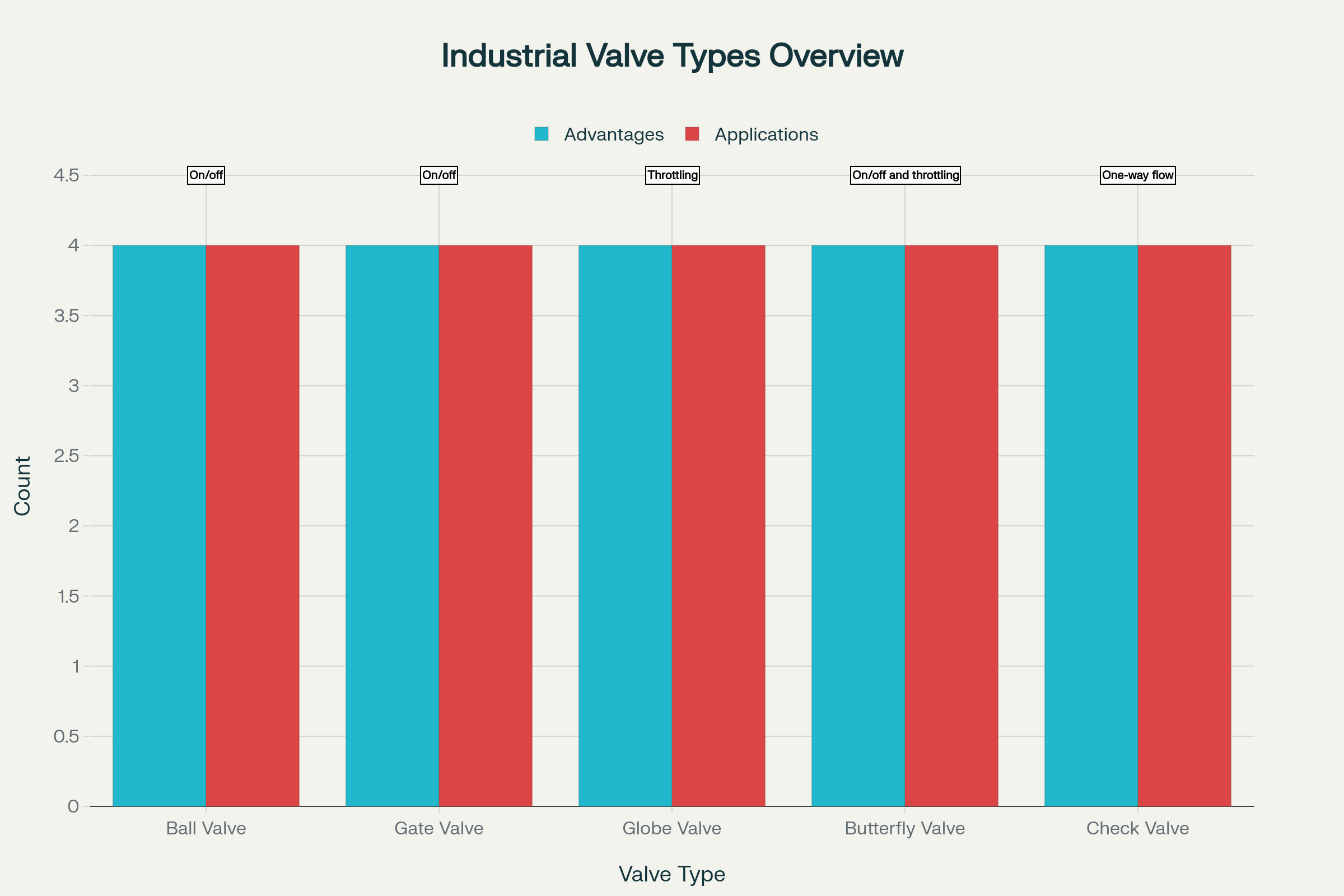

Types of Industrial Valves and Their Applications

Gate valves employ a wedge-shaped gate that moves perpendicular to the flow path, providing full-bore flow when fully open and excellent isolation capabilities. Their design minimizes pressure drop in the fully open position, making them particularly suitable for applications where unobstructed flow is essential, such as water distribution systems and oil pipelines. However, gate valves are primarily designed for on/off service rather than throttling applications.

Globe valves feature a disk that moves parallel to the flow direction, offering superior throttling capabilities and precise flow control. The tortuous flow path through globe valves creates higher pressure drops but enables excellent regulation of flow rates, making them indispensable in steam systems, high-pressure control applications, and processes requiring fine flow adjustment.

Butterfly valves use a rotating disk positioned in the center of the pipe to control flow, offering lightweight construction and compact design. These valves provide good throttling capabilities while maintaining relatively low costs, making them popular for large-diameter applications such as HVAC systems, water treatment facilities, and industrial processes where space and weight constraints are significant factors.

Check valves operate automatically to prevent reverse flow, protecting equipment and maintaining process integrity without requiring external control. These valves are essential in pump systems, pipeline protection applications, and any process where backflow could cause contamination or equipment damage

Valve Selection Criteria for Industrial Applications

Selecting the appropriate valve for industrial applications requires comprehensive analysis of multiple technical and operational factors. Fluid characteristics represent the primary consideration, encompassing viscosity, corrosiveness, temperature, pressure, and the presence of solid particles. Corrosive fluids demand valves constructed from specialized materials such as stainless steel or exotic alloys, while high-temperature applications require valves designed to maintain sealing integrity under thermal stress.

Pressure and temperature ratings must align with system operating conditions, including both normal operations and potential upset conditions. Underestimating these parameters can lead to catastrophic failures, while over-specification results in unnecessary costs and potentially oversized equipment that performs poorly under normal operating conditions.

Flow control requirements determine whether an application needs simple on/off control or precise throttling capabilities. Applications requiring only isolation service may utilize gate or ball valves, while processes demanding variable flow control necessitate globe or butterfly valves designed for throttling service.

Material compatibility extends beyond the valve body to include all wetted components such as seats, seals, and trim materials. Chemical compatibility charts and manufacturer recommendations guide material selection to ensure long-term reliability and prevent premature failure due to chemical attack or incompatibility.

Actuation requirements influence both initial costs and operational complexity. Manual valves offer simplicity and cost-effectiveness for accessible locations with infrequent operation, while automated valves provide precise control and enable remote operation in hazardous or inaccessible locations.

Industrial Valve Applications Across Key Sectors

Oil, Gas, and Petrochemical Industries

The oil and gas sector represents the largest consumer of industrial valves, accounting for approximately 35% of the global valve market[applications_df]. These applications demand valves capable of handling extreme pressures, temperatures, and corrosive media while maintaining zero-leakage performance for safety and environmental compliance. Ball valves and gate valves dominate upstream applications, providing reliable isolation and flow control in drilling operations, production facilities, and gathering systems.

Refinery operations utilize sophisticated valve systems for process control, including globe valves for precise flow regulation in distillation columns and butterfly valves for large-diameter service in cooling water systems. The industry’s emphasis on safety drives demand for fire-safe valves, emergency shutdown systems, and valves meeting stringent API specifications.

Power Generation and Energy Sector

Power plants rely extensively on control valves for steam generation, turbine control, and cooling systems, with 18% market share in the industrial valve sector[applications_df]. Globe valves serve critical roles in feedwater control, superheater attemperation, and turbine bypass systems, where precise flow control directly impacts plant efficiency and safety.

Steam systems require valves designed for high-temperature, high-pressure service, often incorporating specialized trim materials and designs to handle the unique challenges of steam applications. Butterfly valves and ball valves provide isolation and control in cooling water systems, while safety valves and pressure relief valves ensure protection against overpressure conditions.

The transition toward renewable energy sources is creating new valve requirements for hydrogen infrastructure, carbon capture systems, and energy storage applications, driving innovation in valve materials and designs.

Water and Wastewater Treatment

Water treatment facilities utilize valves for process control, chemical feed systems, and distribution networks, representing 12% of the industrial valve market[applications_df]. Butterfly valves excel in large-diameter water transmission lines due to their lightweight construction and cost-effectiveness, while gate valves provide reliable isolation in distribution systems.

Chemical feed systems require globe valves and diaphragm valves capable of handling corrosive chemicals while maintaining precise flow control. The industry’s emphasis on reliability and minimal maintenance drives selection of corrosion-resistant materials and designs optimized for long service life.

Chemical Processing Industries

Chemical processing applications demand valves capable of handling diverse and often aggressive media, accounting for 15% of the valve market[applications_df]. Material selection becomes critical, with stainless steel and exotic alloys frequently required to resist chemical attack. Ball valves and globe valves dominate these applications, often incorporating specialized sealing systems and materials to prevent leakage of hazardous substances.

Process control requirements in chemical plants drive demand for precise throttling capabilities, making globe valves and control valves with sophisticated trim designs essential for maintaining product quality and process efficiency

.

Smart Valves and Digital Transformation

The integration of Internet of Things (IoT) technologies and artificial intelligence is revolutionizing valve design and operation, creating “smart valves” capable of autonomous monitoring, predictive maintenance, and real-time optimization. These advanced systems incorporate sensors for measuring pressure, temperature, flow rates, vibration, and position, transmitting data wirelessly to central control systems for analysis and action.

Remote monitoring capabilities enable operators to assess valve performance from centralized control rooms, reducing the need for field inspections and enabling faster response to abnormal conditions. Real-time data collection facilitates predictive maintenance strategies that identify potential failures before they occur, minimizing unplanned downtime and extending equipment life.

Automated control systems integrated with smart valves optimize process performance by continuously adjusting valve positions based on real-time process conditions. Machine learning algorithms analyze historical data to identify patterns and optimize valve operation for energy efficiency, product quality, and safety.

The adoption of smart valve technologies varies by application, with 81% adoption in automated control and 72% in real-time diagnostics, while emerging technologies like AI/ML integration show 35% current adoption but 15.2% growth rates[smart_valve_df]. Implementation costs range from medium to very high depending on the technology, with return on investment typically achieved within 12 to 48 months[smart_valve_df].

Valve Maintenance and Reliability

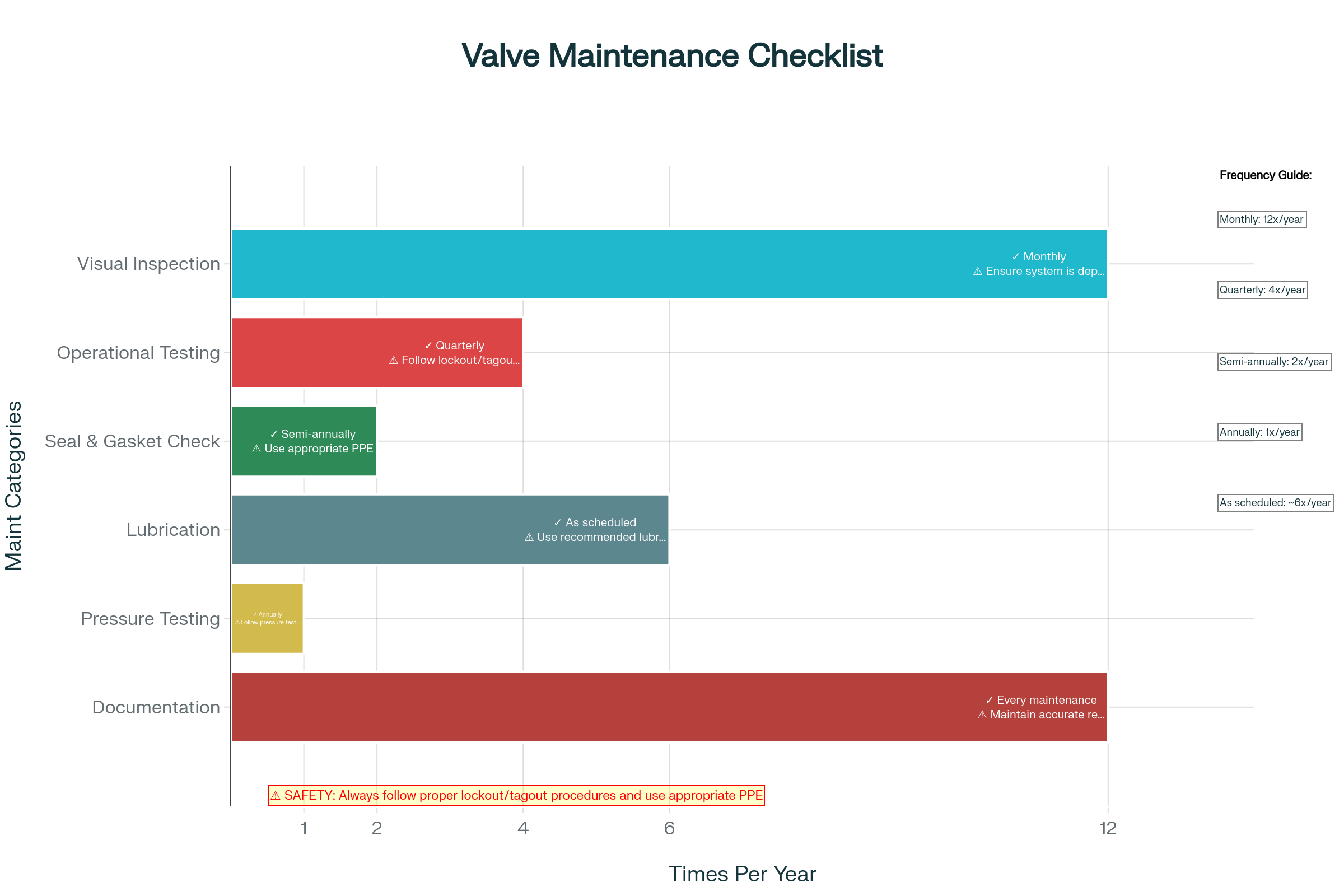

Proper maintenance represents the cornerstone of valve reliability and longevity, directly impacting operational safety, efficiency, and costs. Preventive maintenance programs incorporating regular inspections, lubrication, and component replacement significantly reduce the risk of unexpected failures and extend valve service life.

Visual inspections should examine valve bodies for corrosion, cracks, and external leakage, while operational testing verifies smooth operation and proper response times. Seal and gasket maintenance requires regular inspection for wear, cracking, and proper seating, with timely replacement preventing costly leakage incidents.

Lubrication programs must consider manufacturer recommendations, environmental conditions, and service requirements to ensure optimal performance while preventing contamination. Modern maintenance strategies increasingly incorporate condition monitoring technologies that track valve performance parameters and alert operators to developing problems before failures occur.

Documentation of maintenance activities, findings, and corrective actions provides valuable data for optimizing maintenance intervals, identifying recurring problems, and demonstrating regulatory compliance. Computerized maintenance management systems (CMMS) facilitate tracking of maintenance schedules, spare parts inventory, and performance trends.

Common Valve Problems and Solutions

Industrial valves encounter numerous operational challenges that can impact performance, safety, and reliability. Leakage represents the most common valve problem, typically resulting from worn seals, damaged seats, improper installation, or material incompatibility. Solutions involve systematic diagnosis to identify leak sources, followed by appropriate repairs such as seal replacement, seat refurbishment, or valve adjustment.

Corrosion and erosion damage valve components over time, particularly in aggressive service conditions involving high temperatures, corrosive chemicals, or abrasive media. Prevention strategies include proper material selection, protective coatings, and regular inspections to identify early signs of deterioration.

Blockage and sticking occur when debris accumulates in valve internals or when corrosion products impede valve operation. Solutions involve thorough cleaning, proper filtration upstream of valves, and selection of valve designs that minimize debris accumulation.

Cavitation in liquid service can cause significant damage to valve trim and seats, resulting from pressure drops that cause vapor bubble formation and subsequent collapse. Mitigation strategies include proper valve sizing, anti-cavitation trim designs, and system modifications to reduce pressure drops.

Material Advantages: Stainless Steel Valves

Stainless steel has emerged as the preferred material for many industrial valve applications due to its exceptional combination of corrosion resistance, strength, and versatility. The chromium content in stainless steel creates a passive oxide layer that provides superior resistance to rust and chemical attack compared to carbon steel or other materials.

Temperature resistance enables stainless steel valves to perform effectively across wide temperature ranges, from cryogenic applications to high-temperature steam service. This versatility reduces inventory requirements and simplifies material selection for facilities with diverse operating conditions.

Hygienic properties make stainless steel valves ideal for pharmaceutical and food processing applications where cleanliness and contamination prevention are paramount. The smooth surface finish facilitates cleaning and sterilization while resisting bacterial growth and product adhesion.

Durability and longevity translate to lower total cost of ownership despite higher initial investment costs. Stainless steel valves typically require less frequent maintenance and replacement compared to valves constructed from other materials, particularly in corrosive environments.

Pressure resistance capabilities allow stainless steel valves to handle high-pressure applications that would damage valves made from weaker materials. This strength advantage becomes particularly important in power generation, oil and gas, and chemical processing applications.

Industry Standards and Certifications

Compliance with industry standards ensures valve quality, safety, and performance while facilitating global trade and regulatory approval. API (American Petroleum Institute) standards dominate oil and gas applications, with API 600 covering steel gate valves and API 607 addressing fire-safe testing requirements.

ASME (American Society of Mechanical Engineers) standards encompass pressure vessel and piping applications, with ASME B16.34 governing valve design, materials, and testing. These standards ensure valves meet specific pressure, temperature, and safety requirements for demanding industrial applications.

ISO (International Organization for Standardization) standards provide global harmonization for valve specifications, facilitating international procurement and ensuring consistent quality levels. ISO certification demonstrates manufacturer commitment to quality management systems and continuous improvement.

CE certification enables valve sales within the European Union while demonstrating compliance with safety, health, and environmental protection requirements. Multiple certifications often apply to single valve designs, providing flexibility for global applications and reducing procurement complexity.

Global Market Trends and Future Outlook

The industrial valve market demonstrates robust growth prospects, with analysts projecting expansion from $85 billion in 2025 to $122-250 billion by 2032-2035, representing compound annual growth rates of 4.2% to 12.8%. This growth is driven by infrastructure development, energy sector investments, and increasing adoption of automation technologies.

Regional growth patterns show Asia Pacific leading with 4.6% CAGR, driven by rapid industrialization in China and India. India demonstrates the highest growth potential at 5.1% CAGR, supported by infrastructure initiatives and manufacturing expansion under government programs like Make in India.

Technology trends are reshaping the valve industry, with smart valves, IoT integration, and artificial intelligence creating new market opportunities. The shift toward renewable energy sources requires new valve technologies for hydrogen infrastructure, carbon capture systems, and energy storage applications.

Sustainability initiatives drive demand for energy-efficient valves, fugitive emission control, and materials that reduce environmental impact. Regulatory pressure for reduced emissions and improved safety is accelerating adoption of advanced valve technologies and stricter performance standards.

Automation growth continues accelerating across all industrial sectors, with automated valves showing 4.7% CAGR compared to 4.2% for manual valves. This trend reflects industrial priorities for improved safety, efficiency, and reduced labor requirements in hazardous environments.

Conclusion

Industrial valves represent the circulatory system of modern industrial infrastructure, enabling precise control of process flows while ensuring safety, efficiency, and environmental compliance. The diversity of valve types, materials, and technologies available today provides solutions for virtually any industrial application, from the extreme conditions of oil and gas production to the precision requirements of pharmaceutical manufacturing.

The industry’s future is being shaped by digital transformation, sustainability imperatives, and evolving energy landscapes. Smart valve technologies promise unprecedented levels of operational insight and control, while advanced materials and designs address increasingly demanding service conditions. Market growth projections reflect strong underlying demand driven by global industrialization, infrastructure modernization, and the transition to cleaner energy sources.

Success in valve selection and application requires comprehensive understanding of technical requirements, industry standards, and emerging technologies. As industrial processes become more complex and demanding, the importance of proper valve selection, installation, and maintenance will only continue to grow. Organizations that invest in understanding these critical components and leveraging advanced technologies will be best positioned to achieve operational excellence in an increasingly competitive global marketplace.

The industrial valve industry stands at the threshold of significant transformation, with opportunities for those who embrace innovation while maintaining focus on fundamental engineering principles. From traditional mechanical designs to AI-powered smart systems, valves will continue evolving to meet the challenges of tomorrow’s industrial applications while delivering the reliability and performance that modern industry demands.